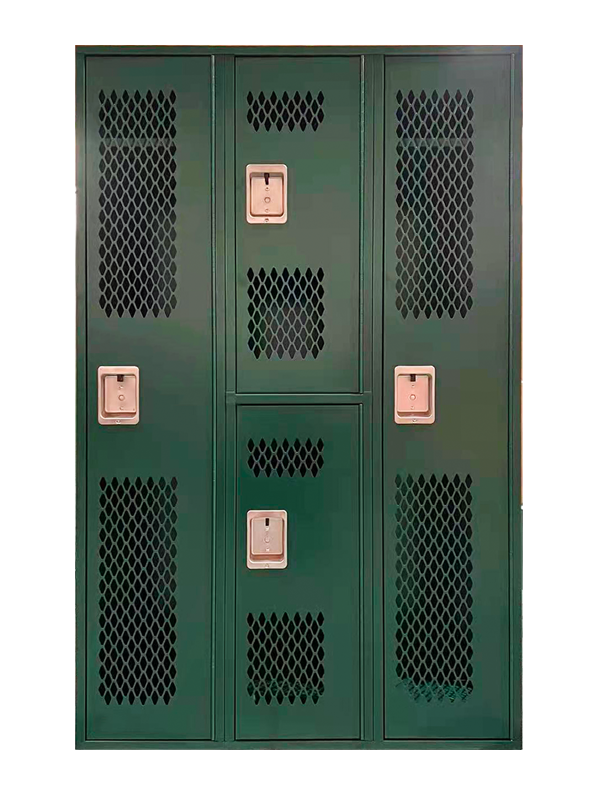

Welded locker are generally considered to be safer than other types of lockers, particularly when it comes to security and structural integrity. Here are some reasons why welded lockers are often perceived as safer:

Enhanced Security: Welded lockers have fewer points of vulnerability compared to lockers assembled with nuts and bolts or rivets. The seamless construction of welded lockers reduces the risk of tampering or forced entry. With no visible fasteners to dismantle, it becomes more challenging for unauthorized individuals to break into the lockers.

Reduced Risk of Breakage: The welding process creates a strong and durable bond between the locker components, making the locker less prone to structural failures or breakage. This is especially important in high-traffic areas where lockers may be subject to heavy use and rough handling.

Sturdiness: Welded lockers tend to be more robust and resistant to deformation, providing a safer storage option for various items. The sturdy construction can help prevent accidents, such as lockers collapsing or tipping over.

Fire Resistance: Depending on the material used for construction, welded lockers can offer better fire resistance compared to lockers made of certain other materials. Steel-welded lockers, for example, are generally more fire-resistant than lockers made of wood or plastic.

Improved Hygiene: Welded lockers often have smoother surfaces without visible seams or crevices where dirt and bacteria can accumulate. This makes cleaning and maintaining proper hygiene standards easier, contributing to a safer environment.

English

English 中文简体

中文简体