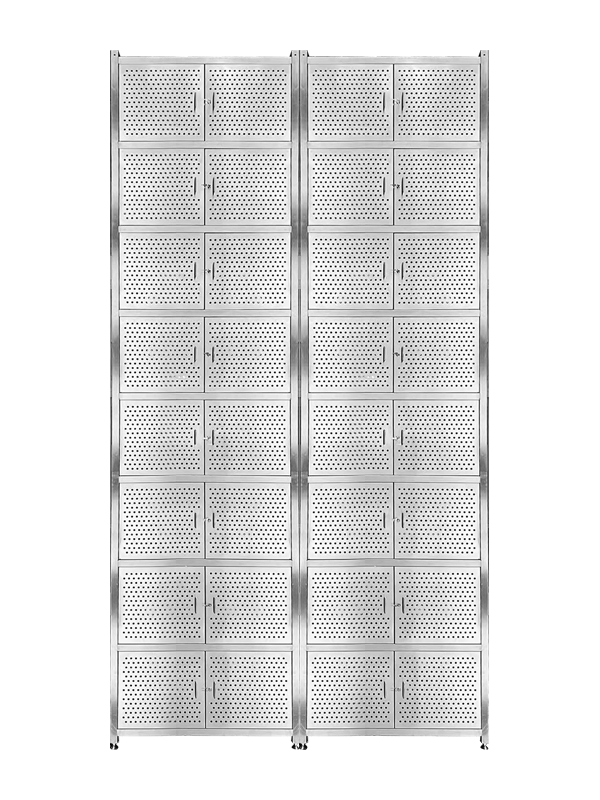

The durability of the hardware and fasteners used in stainless steel locker can vary depending on several factors, including the quality of materials, the grade of stainless steel, and the specific design and manufacturing standards. However, stainless steel hardware and fasteners are generally known for their durability and resistance to corrosion. Here are some key considerations:

Stainless Steel Grade: The grade of stainless steel used in locker hardware and fasteners is a critical factor. Common grades include 304 and 316 stainless steel. Grade 316 stainless steel, often referred to as marine-grade stainless steel, is the most corrosion-resistant and is ideal for environments with high humidity or exposure to saltwater. It provides excellent durability and longevity.

Corrosion Resistance: Stainless steel is chosen for locker hardware and fasteners precisely because of its exceptional corrosion resistance. It is resistant to rust, staining, and corrosion even when exposed to moisture, humidity, or harsh chemicals. This property makes stainless steel hardware and fasteners highly durable in a variety of conditions.

Quality of Manufacturing: The durability of hardware and fasteners also depends on the quality of their manufacturing. High-quality manufacturing processes, including precision machining and finishing, contribute to the strength and longevity of these components. Well-made hardware is less likely to fail or deteriorate prematurely.

Proper Installation: Correct installation practices are essential to maximize the durability of stainless steel hardware and fasteners. This includes using appropriate fasteners, following manufacturer's guidelines for installation, and ensuring that they are torqued to the recommended specifications. Proper installation helps prevent issues like loosening or failure over time.

Maintenance: While stainless steel is highly resistant to corrosion, routine maintenance is still recommended to extend the life of hardware and fasteners. Periodic cleaning with a mild detergent and a soft cloth can remove dirt, grime, and fingerprints. Maintenance can help preserve the appearance and function of the hardware.

Environmental Factors: The specific environmental conditions where the lockers are installed can impact the durability of the hardware and fasteners. For example, lockers located in coastal areas with exposure to saltwater may require more frequent maintenance to protect against corrosion.

Manufacturer Reputation: Choosing lockers from reputable manufacturers known for their quality and craftsmanship can ensure that the hardware and fasteners meet high standards for durability. Reputable manufacturers often provide warranties to back the durability of their products.

English

English 中文简体

中文简体